Mipira 440 yosapanga dzimbiri yolondola kwambiri

Mipira 440 yachitsulo chosapanga dzimbiri imaphatikiza kuuma kodabwitsa ndi kukana kwakukulu kwa dzimbiri chifukwa cha madzi, nthunzi, mpweya komanso mafuta, mafuta ndi mowa.Kumapeto kwapamwamba kwambiri komanso kulolerana bwino kwambiri kumapangitsa kuti zitsulo zosapanga dzimbiri zamtunduwu zikhale zabwino kwambiri kuti zigwiritsidwe ntchito muzitsulo zosapanga dzimbiri zokhala ndi mipira yolondola kwambiri, ma valve, zolembera za mpira.

Kufotokozera

| 440 mipira yachitsulo chosapanga dzimbiri | |

| Diameters | 2.0mm - 55.0mm |

| Gulu | G10-G500 |

| Kugwiritsa ntchito | zolembera za mpira, ma valve oyeretsera mafuta, zolembera za mpira |

Kuuma

| 440 mipira yachitsulo chosapanga dzimbiri | |||

| Malinga ndi DIN 5401:2002-08 | Malinga ndi ANSI/ABMA Std.10A-2001 | ||

| chatha | mpaka |

| |

| zonse | zonse | 55/60 HRC | 55/62 HRC |

Kufanana Kwazinthu

| 440 mipira yachitsulo chosapanga dzimbiri | |

| AISI/ASTM(USA) | 440b |

| VDEh (GER) | 1.4112 |

| JIS (JAP) | Zithunzi za SUS440B |

| BS (UK) | - |

| NF (France) | - |

| ГОСТ(Russia) | - |

| GB (China) | - |

Chemical Composition

| 440 mipira yachitsulo chosapanga dzimbiri | |

| C | 0.85% - 0.95% |

| Si | ≤1.00% |

| Mn | ≤1.00% |

| P | ≤0.04% |

| S | ≤0.015% |

| Cr | 17.00% - 19.00% |

| Mo | 0.90% - 1.30% |

| V | 0.07% - 0.12% |

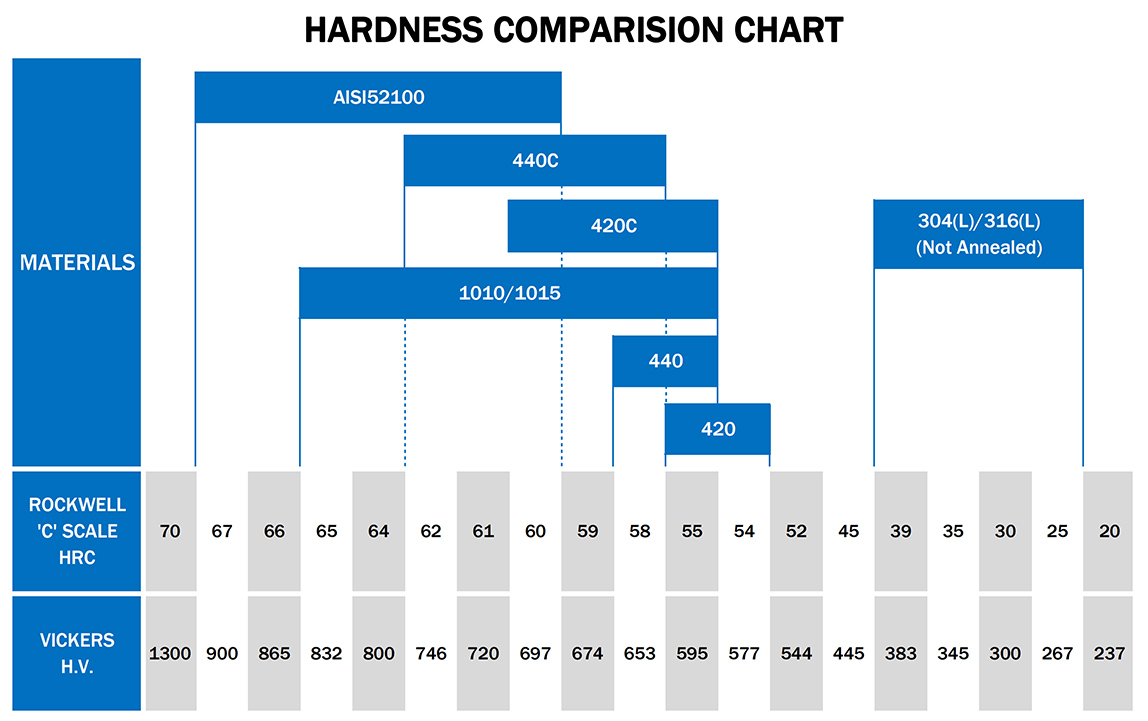

Tchati Chofananitsa Chakuuma

Ubwino Wathu

● Takhala tikugwira ntchito yopanga mpira wachitsulo kwa zaka zoposa 26;

● Timapereka kukula kwakukulu kochokera ku 3.175mm mpaka 38.1mm.Kukula Non-standard ndi gauges akhoza kupanga pansi pempho lapadera (monga 5.1mm, 5.15mm, 5.2mm, 5.3mm 5.4mm kwa njanji mpando; 14.0mm kwa cam shaft ndi CV olowa, etc.);

● Tili ndi masheya ambiri.Zambiri za kukula kwake (3.175mm ~ 38.1mm) ndi geji (-8 ~ + 8) zilipo, zomwe zingathe kuperekedwa nthawi yomweyo;

● Gulu lililonse la mipira limawunikiridwa ndi makina apamwamba kwambiri: tester roundness, roughness tester, metallographic analysis microscope, hardness tester (HRC ndi HV) kutsimikizira ubwino.

FAQ

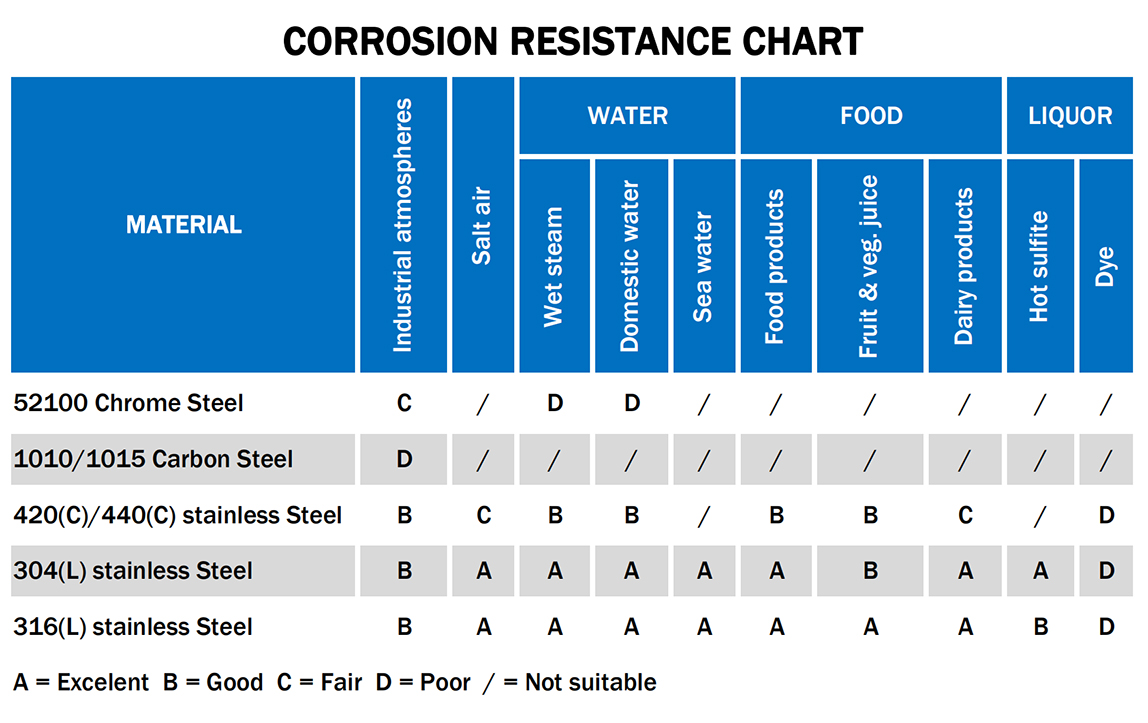

Q: Kodi ndingasankhe bwanji mtundu woyenera wazitsulo zosapanga dzimbiri (304(L)/316(L)/420(C)/440(C))?Kodi pali kusiyana kotani pakati pa mipira 300 ndi 400 ya zitsulo zosapanga dzimbiri?

Yankho: Kuti tisankhe mtundu woyenera wachitsulo wa mipira yachitsulo chosapanga dzimbiri, tiyenera kudziwa bwino za mtundu uliwonse komanso kagwiritsidwe ntchito ka mipirayo.Mipira yosapanga dzimbiri yomwe imagwiritsidwa ntchito kwambiri imatha kugawidwa m'magulu awiri: mndandanda wa 300 ndi mndandanda wa 400.

Mipira yachitsulo yosapanga dzimbiri 300 ya mndandanda wa "austenitic" imakhala ndi chromium ndi faifi tambala ndipo simaginito (kwenikweni imakhala ndi maginito otsika kwambiri. Osakhala ndi maginito amafunikiranso kutentha).Kawirikawiri amapangidwa popanda njira yochizira kutentha.Ali ndi kukana kwa dzimbiri bwino kuposa mndandanda wa 400 (kwenikweni, kukana kwa dzimbiri kwapamwamba kwambiri kwa gulu lopanda utoto. Ngakhale kuti mipira 300 yonse imakhala yosamva, komabe mipira 316 ndi 304 imawonetsa kukana kosiyana ndi zinthu zina. Kuti mumve zambiri, chonde onani masamba mipira yosiyanasiyana yachitsulo chosapanga dzimbiri) .Ndiwocheperako pang'ono, kotero amatha kugwiritsidwa ntchito posindikiza.Mipira yazitsulo zosapanga dzimbiri 400 imakhala ndi mpweya wambiri, womwe umapangitsa kuti ikhale maginito komanso kuuma kwambiri.Zitha kutenthedwa mosavuta ngati mipira yachitsulo ya chrome kapena mipira yachitsulo ya carbon kuti ionjezere kuuma.Mipira ya zitsulo zosapanga dzimbiri 400 imagwiritsidwa ntchito kwambiri pazinthu zomwe zimafuna kusagwira madzi, mphamvu, kulimba komanso kukana kuvala.

Q: Kodi chitsimikizo chanu chili bwanji?

A: Mipira yonse yopangidwa ndi 100% yosanjidwa ndi kapamwamba kosankhira ndikuwunikiridwa ndi chowunikira cha photoelectric surface defect.Pamaso ma CD zitsanzo mipira kuchokera maere ndi kutumiza anayendera komaliza kuti aone roughness, roundness, kuuma, kusiyanasiyana, kuphwanya katundu ndi kugwedera motsatira muyezo.Ngati zofunikira zonse zakwaniritsidwa, lipoti loyendera lidzapangidwa kwa kasitomala.Laborator yathu yapamwamba kwambiri ili ndi makina olondola kwambiri komanso zida: Rockwell hardness tester, Vickers hardness tester, makina opondereza, mita ya roughness, mita yozungulira, comparator m'mimba mwake, maikulosikopu ya metallographic, chida choyezera kugwedezeka, ndi zina zambiri.

Magulu azinthu

-

Foni

-

Imelo

-

Whatsapp

-

Skype

-

Pamwamba